During the initial phase of production, a mold is developed based on a nominal model. Nevertheless, there is often a discrepancy between the theoretical design and the practical realities of industrial manufacturing. Creating a high-quality mold is essential for producing components that adhere to the required technical standards. In the production of new electric vehicles, molds are employed to fabricate a range of automotive parts, including car interiors, battery compartment covers, A-surfaces, and precision electronic components. To stay competitive, manufacturers need to adopt more efficient methods for inspecting molds, streamlining processes to save both time and costs.

Manufacturer of components for new electric vehicles

The customer specializes in the design, processing, production and sale of composite products. The company excels in the production of new components for electric vehicles, which have been supplied to well-known manufacturers.

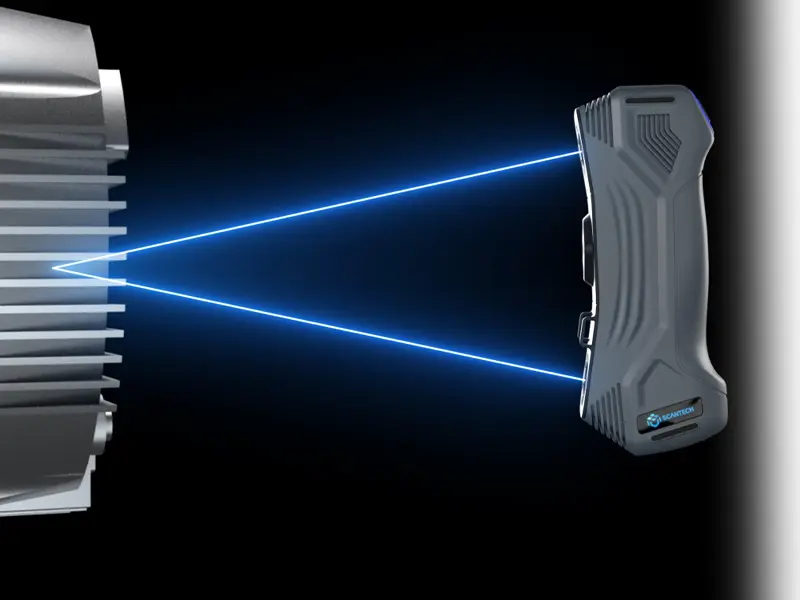

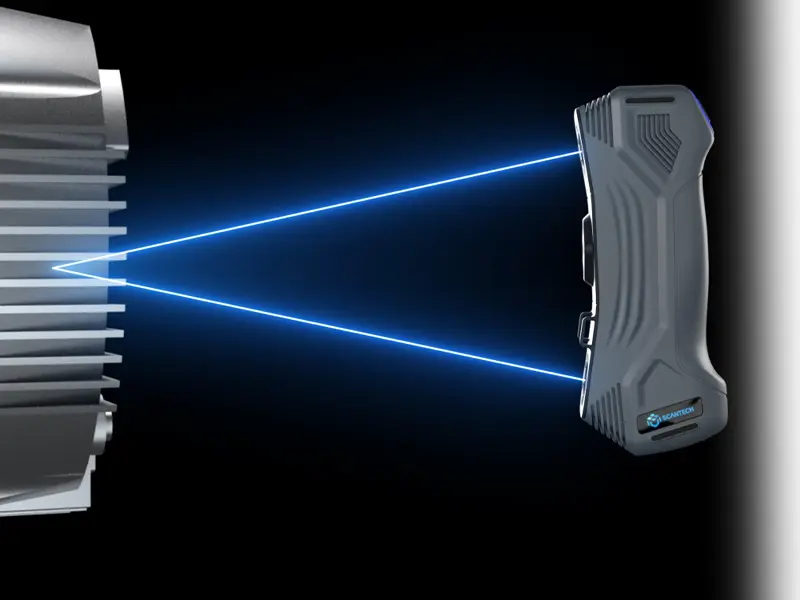

In this project, the customer uses the SIMSCAN portable 3D scanner to measure the molds used to create the battery box covers, to obtain the complete 3D data and to ensure that they meet the technical requirements.

Inspect molds to produce reliable auto parts

The battery pack, as a critical component of new energy vehicles, requires a strong and lightweight top cover to support and protect it from external impacts.

In this case, the molds for the battery compartment covers are made of glass fiber reinforced plastic (FRP), a new composite material with a high strength-to-weight ratio, suitable for making battery compartment covers for new energy vehicles.

The customer proposed to inspect GD&T including flatness of various automotive FRP molds. This way, they can verify that the molds meet specifications and that the battery box cover meets delivery standards. This facilitates the production of reliable and efficient components.

Difficulty 3D scanning complicated molds

Deformation – FRP has low rigidity, which means molds can warp during manufacturing. Additionally, FRP products are more likely to warp than metal products.

Large size – molds are large and complex, so measuring takes time and labor. Their large size poses challenges for the measurement process.

Limited areas – molds have many corners, vertical surfaces and narrow spaces, inaccessible to conventional measurement methods. Comprehensive data is difficult to obtain.

Disadvantages of traditional measurement methods

The bubble level test was the common method for checking the mold surface, but it had many disadvantages:

It was only able to detect whether the surface was flat or not, but not the exact size and extent of any defects, such as bumps. This made it difficult to accurately repair the mold and sometimes resulted in the entire mold being scrapped, wasting money.

It generated no test reports or visual results, so staff had to rely on their own experience and judgment to correct the mold. This required a high level of professionalism from the team.

A large amount of manpower and resources were required to examine each product, reducing the productivity of mold processing.

3D scanner used: SIMSCAN

Scanning process: The operator attached some targets on the mold surfaces, and then used the SIMSCAN portable 3D laser scanner to scan the surfaces, quickly capturing high-density spots. The scanned data was processed by 3D software and compared with the CAD model. Finally, the operator obtained inspection reports to intuitively identify deviations.

Scanning time: 8 minutes for the smallest mold (about 60cm*25cm) and 15 minutes for the largest mold (about 200cm*100cm*50cm).

Advantages of 3D scanning molds

Fast scanning for high efficiency

With 17 blue laser crosses and a robust algorithm, SIMSCAN scans quickly with a measurement speed of up to 2.8 million measurements/s. It can scan a large area up to 700*600mm, which makes it very efficient for measuring large workpieces.

Excellent performance for the finest details

With high resolution and accuracy of 0.020mm, it can capture high-quality 3D feature data. Additionally, SIMSCAN features two cameras just 130mm apart, making it easy to capture accurate 3D data for tight spaces.

Portable, compact and flexible

SIMSCAN is a portable, handheld and compact 3D laser scanner that allows engineers to measure parts over a long session without causing too much fatigue. It can be easily transported to take measurements even in difficult conditions.

Real-time reporting for intuitive analysis

The acquired data can be imported into 3D inspection software for comparison and analysis with the original CAD model. It can generate easy-to-understand color maps to provide precise data guidance for subsequent product repair and mold modification.

latest posts published

What can 3D scanning do for reverse engineering?

Ultimaker opens new possibilities for industrial printing!

Fields of applicability of 3D technology

3D scanning improves inspection and maintenance of race cars

ABS filaments for 3D printing

PET filaments for the 3D printer

How to optimize mold inspection for auto parts

The best large format 3D printers. The buyer’s guide

How architectural models are created using additive manufacturing